Hits:3999 Belong to:Software Product

一、简介

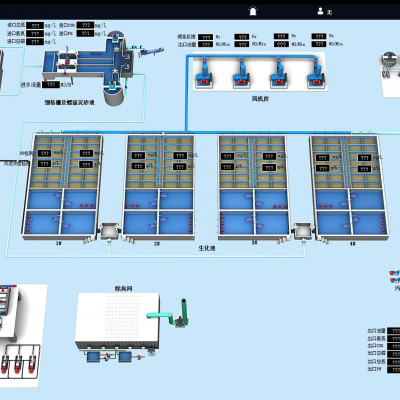

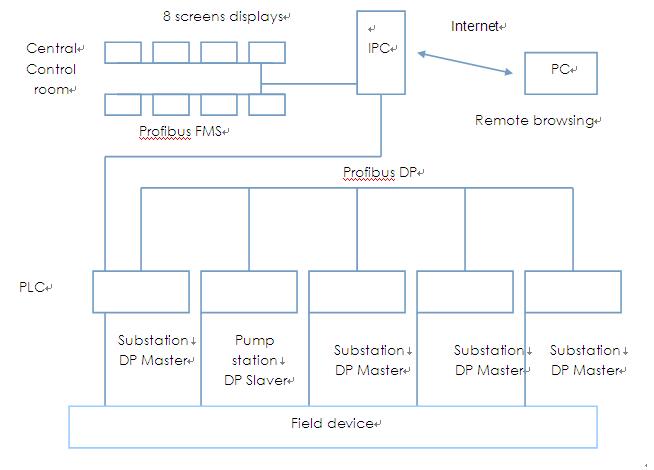

本扩散型控制系统由计算机和PLC控制器组成

二、功能

(一)不同机型功能对照表

| 物品 | 功能 | 一个模型 | B款 | C型 | D型 |

| 1个 | 数据采集 | 是的 | 是的 | 是的 | 是的 |

| 2个 | 警告 | 是的 | 是的 | 是的 | 是的 |

| 3个 | 遥控 | 是的 | 是的 | 是的 | 是的 |

| 4个 | 无线遥测 | 是的 | |||

| 5个 | 报告数据库 | 是的 | 是的 | ||

| 6个 | 接口扩展 | 是的 | 是的 | ||

| 7 | 进口工控机 | 是的 | |||

| 8个 | 中国工控机 | 是的 | |||

| 9 | 进口PLC | 是的 | 是的 | ||

| 10 | 中国PLC | 是的 | |||

| 11 | 进口触控面板 | 是的 | |||

| 12 | 中文触摸屏 | 是的 | |||

| 13 | 进口转换器 | 是的 | 是的 | ||

| 14 | 中文转换器 | 是的 | 是的 | ||

| 15 | 打印机 | 是的 | 是的 | ||

| 16 | 投影仪 | 是的 | 是的 | ||

| 17 | UPS | 是的 | 是的 | 是的 | 是的 |

| 18 | 防雷 | 是的 | 是的 | 是的 | 是的 |

| 19 | 进口低压电器 | 是的 | 是的 | ||

| 20 | 中国低压电器 | 是的 | 是的 | 是的 |

(二)功能说明:

A Data acquisition: Following data can be displayed in central control room

1、 Manual/auto signal, running signal, error signal of electrical equipment

2、 Power signal, start and stop control signal

3、 Process flowchart signal, liquid level range

4、 Gathering analog signals, such as temperature, pressure, flow,, concentration, turbidity, dissolved oxygen, PH, current

5、 Instant flow rate, cumulant per hour/day/month/year

B Warning:

1、 Air exposure pump status display: Green &Red light indicates good running and over load warning

2、 Draining pump status display: Green &Red light indicates good running and over load warning

3、 Blender status display: Green &Red light indicates good running and over load warning

4、 Electric valve status display: Green &Red light indicates good running and over load warning

5、 Blower status display: Green &Red light indicates good running and over load warning

6、 Turbidity status display: Green &Red light indicates normal and excessive range

7、 PH status display: Green &Red light indicates normal and excessive range

8、 Output water level status display: Green &Red light indicates normal and excessive water level

9、Chlorine leakage warning

C Remote control:

1、 Local and remote control for Air exposure pump

2、 Local and remote control for sludger pump (Through wireless transmission to central control room)

3、 Local and remote control for blower and agitator pump

4、 Remote setting and control for Alum volume release

5、 Remote setting and control for Chlorine volume release

6、 Remote setting and control for electric butterfly bamper(valve)

Realization of full automatic control for the whole water production course through monitoring clean-water reservoir water level:

When water level is lower than preset figures, the system will activate butterfly bamper, Filter pool, Chlorine and alum release, etc;

when water level is higher than preset figures, the whole production will be halted.

D. Wireless telemetry:

The pressure tap in pipeline can be transmitted wirelessly to the industrial computer in central control room

E Report Database:

1. Daily report for Turbidity, PH value, water level, residual chlorine, flow of finished water; Test corresponding basicity, Nitrogen&Ammonia, residual chlorine, total phosphorus, organics, suspended solids, PH, Turbidity, activity of activated sludge, medicating flow, pipe network pressure

2. Daily cumulative monthly report for Medicine release, finished water flow.

3. Monthly cumulative yearly report for Medicine release, finished water flow.

F Interface expansion: sewage plant expansion

3. Advantages:

1、 Can assure high quality and safe water supply

2、 Labor productivity is so greatly improved that 50%-70% managing and working staff can be reduced.

3、 When there is Chlorine leakage, the central control room can monitor and control to increase safety

4、 Auto-chlorination can protect the environment and workers as all operation is done in central control room

5、 Improve management of water plant; auto generated production report can be stored in computer as reference and decision making

6、 Reduce cost on staff

7、 Save Chlorine and Alum consumption