Hits:3450 Belong to:Software Product

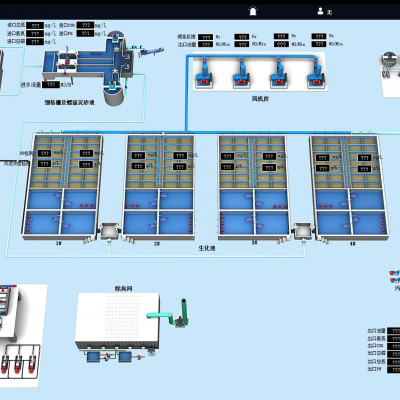

系统组成

大米加工厂自动控制系统由监控计算机、PLC、检测传感器(含液位开关)、电气控制柜等组成

。控制柜接受PLC的指令控制设备运行、检测传感器和继电器。在这个过程中,大米加工的所有信号都可以通过计算机进行监控和控制。

监控计算机和PLC

上位机通过以太网接口或RS232/RS485接口与PLC进行采集。

在监控和数据采集系统方面,我们使用北京昆仑东泰的MCGS或北京组态王的King Series。

西门子S7-200或施耐德Twido系列PLC将根据开关量的多少进行配置。

PLC具有相应的DI、AI输入接口和DO、AO输出接口。

电机启停、故障反馈、料位开关等所有信号均为DI输入。

电机电流、料位等模拟信号为AI输入。

所有电机的启停都是DO输出。

大米抛光机电机转速的变频调节信号为AO输出。

通过监控和数据采集系统配置后,人机界面将是一个简单的大米加工流程图,其中每个输入和输出信号将以数字或条形图的形式显示。并且可以在上位机修改或初始化PLC程序。

电气控制柜内

装有继电器和接触器,实现对所有设备电机的通断控制。

机柜可现场安装,也可在控制室安装。相应地,有2种模式:现场切换和远程切换。

对于现场模式,用户只能通过机柜上的按钮或进入机柜的按钮设备启动系统。

对于远程模式,可以通过PLC控制电气柜来启动和停止所有大米加工设备。

Through contactors, the start and stop status of all motors can be feed back to PLC and finally to host computer to be displayed and monitored.

Due to different rice quality, we need adopt different polishing speed. So we install frequency converter to receive AO signals from PLC in rice polishing machine to realize frequency control.

Logic control

This auto control system for rice processing plant can not only manage the whole rice production course, but also realize feedback control and logic control.

After receiving return signals from rice huller and level sensor, the PLC can control following equipment according to logical condition of rice processing

So, as there are different rice processing methods, with different matched equipment, and plant upgrade, PLC can adjust the logic control for rice processing more easily.

The most advantage of PLC is to replace the intermediate relays and time relays with software functions. The ladder diagram program usually adopts sequential control design methods with regular programming methods, so that we can modulate the control logic and equipment interlock and control for rice processing, according to different device combination.

Supervisory control computer Operation

In its software interface, there are dynamic displays for all equipment running status:

1. 重力式水稻分级机有红、绿、黄灯指示关闭、开启、错误状态和所有设备的电流,使操作人员一目了然

2. 设备状态和运行情况;

3、配备溢流报警、电流过载报警及相关处理电路,实现预警停机;

4、每个处理单元都有相应的开/关按钮,也可以根据需要屏蔽某些设备(如处理还米时可以关闭水稻分级机前的设备);

5、掌握各种紧急情况下的急停开关。

监控计算机功能:

1、动态显示各工序、生产报表及数据。

2. 如果有任何错误,系统会警告并显示该部分的错误类型,以便我们更轻松地调试设备。

3、权限管理:只有输入密码后,操作人员才能进入操作界面。

4、系统可显示年、月、日并输出大米生产报表:可设置每包重量和扫描包数,转换成相关脉冲。然后系统根据包装重量和数量计算产量。

5、历史数据查询:如上周运行时间、水稻产量等。