Hits:4145 Belong to:Software Product

一、简介

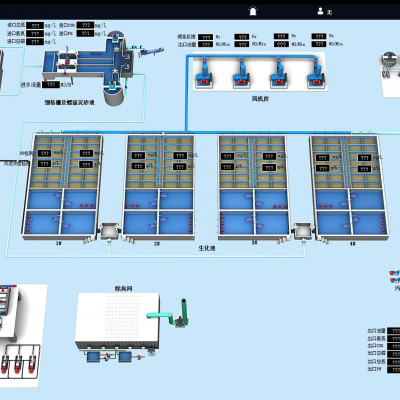

本扩散型控制系统由计算机和PLC控制器组成 .jpg)

二、功能

(一)不同机型功能对照表

| 物品 | 功能 | 一个模型 | B款 | C型 | 评论 |

| 1个 | 数据采集 | 是的 | 是的 | 是的 | |

| 2个 | 警告 | 是的 | 是的 | 是的 | |

| 3个 | 遥控 | 是的 | 是的 | 是的 | |

| 4个 | 无线遥测 | 是的 | |||

| 5个 | 报告数据库 | 是的 | 是的 | ||

| 6个 | 接口扩展 | 是的 | 是的 | ||

| 7 | 进口工控机 | 是的 | |||

| 8个 | 中国工控机 | 是的 | |||

| 9 | 进口PLC | 是的 | 是的 | ||

| 10 | 中国PLC | 是的 | |||

| 11 | 进口触控面板 | 是的 | |||

| 12 | 中文触摸屏 | ||||

| 13 | 进口转换器 | 是的 | 是的 | ||

| 14 | 中文转换器 | 是的 | |||

| 15 | 打印机 | 是的 | 是的 | ||

| 16 | 投影仪 | 是的 | 是的 | ||

| 17 | UPS | 是的 | 是的 | 是的 | |

| 18 | 防雷 | 是的 | 是的 | 是的 | |

| 19 | 进口低压电器 | 是的 | 是的 | ||

| 20 | 中国低压电器 | 是的 | 是的 |

(2) Function description

A. Data acquisition: Following data can be displayed in central control room

1, Intake pump, Pump suction car, Reverse flushing pump, blower, valves and water supply status

2, Raw water turbidity, PH value

3, Instant flow rate during medication, cumulant per hour/day/month/year

4, Output water turbidity, PH, residual chlorine

5, Output water Instant flow rate, cumulant per hour/day/month/year

6, Filter pool water level, clean-water reservoir water level

7, Pressure at pipe network detecting point

B. Warning:

1, Lift pump status display: Green &Red light indicates good running and over load warning

2, Dredge pump truck status display: Green &Red light indicates good running and over load warning

3, Reverse flushing pump status display: Green &Red light indicates good running and over load warning

4, Electric valve status display: Green &Red light indicates good running and over load warning

5, Water-delivery pump status display: Green &Red light indicates good running and over load warning

6, Turbidity status display: Green &Red light indicates normal and excessive range

7, PH status display: Green &Red light indicates normal and excessive range

8, Filter pool, clean-water reservoir status display: Green &Red light indicates normal and excessive water level

9, Chlorine leakage warning

C. Remote control:

1, Local and remote control for Lift pump

2, Local and remote control for Dredge pump truck (Through wireless transmission to central control room)

3, Local and remote control for blower, Reverse flushing pump

4, Remote setting and control for Alum volume release

5, Remote setting and control for Chlorine volume release

6, Remote setting and control for inflow valves and butterfly bamper(valve)

7, Realization of full automatic control for the whole water production course through monitoring clean-water reservoir water level: When water level is lower than preset figures, the system will activate butterfly bamper, Filter pool, Chlorine and alum release, etc; when water level is higher than preset figures, the whole production will be halted.

D. Wireless telemetry:

The pressure tap in pipeline can be transmitted wirelessly to the industrial computer in central control room

E. Report Database:

1. Daily report for:

a.Turbidity, PH value, water level, residual chlorine, flow of finished water

b.Turbidity, PH value of raw water

c. Medicine release flow

d. Pipe network pressure

2. Daily cumulative monthly report for Medicine release, finished water flow.

3. Monthly cumulative yearly report for Medicine release, finished water flow.

F. Interface expansion: Water plant expansion

3. Advantages:

1, Can assure high quality and safe water supply

2, Labor productivity is so greatly improved that 50%-70% managing and working staff can be reduced.

3, When there is Chlorine leakage, the central control room can monitor and control to increase safety

4, Auto-chlorination can protect the environment and workers as all operation is done in central control room

5, 改善水厂管理;自动生成的生产报告可以存储在计算机中作为参考和决策

6 , 减少员工成本

7 , 节省氯和明矾的消耗