Intelligent SCADA System for Wastewater Treatment Plants

Hits:413 Belong to:Software Product

I. Functional

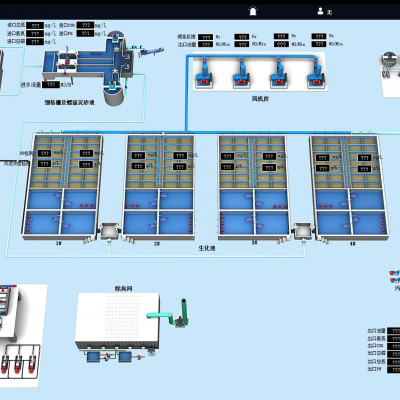

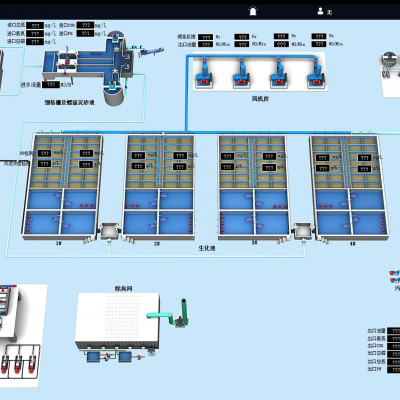

1. Real-Time Monitoring

1. Water Quality Indicators: Real-time collection of influent COD/ammonia nitrogen and effluent TP/SS, with automatic alerts for exceeding standards.

2. Equipment Status: Real-time monitoring of pump/fan/screen operating parameters (current, speed, pressure), with highlighted abnormalities.

3. Process Parameters: Online display of aeration tank DO, sedimentation tank level, and sludge concentration, with support for process flow chart visualization. Replacing manual inspections, reducing on-site inspection workload by 80% and minimizing the risk of excessive emissions.

2. Equipment Management

1. Fault Diagnosis: Automatically identifies anomalies (such as abnormal fan noise and pump overload) based on equipment operating data and provides troubleshooting instructions.

2. Maintenance Reminders: Automatically generates maintenance plans for pump lubrication and screen cleaning based on operating hours and operating conditions.

3. Historical Recording: Stores equipment start and stop records and troubleshooting logs, supporting retrospective analysis.

3. Data Management and Analysis

1. Data Storage: Dual backup of water quality, equipment, and process data, locally and in the cloud, with a retention period of ≥5 years (meeting environmental regulations).

2. Report Generation: Automatically exports daily, weekly, and monthly operational reports (such as water quality compliance rate and energy consumption statistics), with one-click export to Excel/PDF.

3. Trend Analysis: Graphs display water quality fluctuations and energy consumption trends, assisting in optimizing aeration duration and chemical dosage. 4. Remote Control

1. Permission Hierarchy: Supports hierarchical permissions from "Administrator - Operations & Maintenance - Operator." Key operations (such as fan start and stop) require dual authorization.

2. Remote Operation: Remotely control pump speed and valve opening from the central control room or mobile app, quickly shutting down risky links in emergencies.

II. Core Advantages

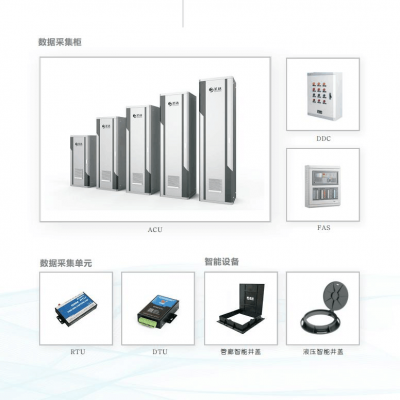

1. Strong Compatibility: Supports integration with mainstream sensor brands (such as Hach, Shimadzu) and PLCs (Siemens, Schneider), eliminating the need to replace existing equipment and reducing retrofit costs.

2. High Stability: Utilizing an industrial-grade hardware architecture, it supports 24/7 continuous operation, with a system failure rate of less than 0.5% and data collection accuracy of ≥99.8%.

3. Compliance: The data format complies with the "Pollutant Discharge Standard for Urban Wastewater Treatment Plants" (GB18918-2002), allowing direct integration with local environmental protection regulatory platforms to avoid non-compliant data reporting.

4. Easy to Use: The interface utilizes a "process flow chart + data card" design, allowing operators to get started in under an hour without requiring specialized IT knowledge.

III. Service Guarantee

1. Deployment Service: We provide a full-process service covering "on-site investigation - solution design - system installation - commissioning and launch," enabling deployment of small and medium-sized wastewater treatment plants within 30 days.

2.Operation and Maintenance Support: We offer a 24/7 technical hotline with a remote troubleshooting response time of ≤ 2 hours and on-site resolution of major issues within 48 hours.

3.Training Service: We provide free hands-on training for both administrators and operators, along with video tutorials and manuals to ensure efficient system operation.

Associated product

Intelligent SCADA System for Waterworks

Intelligent SCADA System for Wastewater Treatment Plants

Cubic garage control system

Chiller group control system

Intelligent SCADA System for Wastewater Treatment PlantsNo information