Intelligent SCADA System for Waterworks

2. Equipment Control: Online monitoring of current, speed, and vibration parameters for pumps, fans, and dosing pumps, enabling automatic fault location.

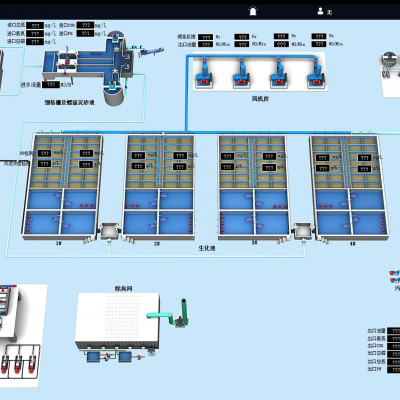

3. Process Visualization: Dynamically displays process flow charts for flocculation and sedimentation, with color-coded warnings for key parameters.

Hits:381 Belong to:Software Product

I. Functional Introduction

1. Full Process Monitoring

1. Water Quality Monitoring: Real-time collection of 18 indicators, including raw water turbidity/ammonia nitrogen, and outlet water residual chlorine/pH. Exceeding standards triggers immediate audible and visual alarms.2. Equipment Control: Online monitoring of current, speed, and vibration parameters for pumps, fans, and dosing pumps, enabling automatic fault location.

3. Process Visualization: Dynamically displays process flow charts for flocculation and sedimentation, with color-coded warnings for key parameters.

2. Intelligent Control

1. Adaptive Dosing: Automatically adjusts coagulant dosage based on raw water turbidity, reducing chemical consumption by 15%;

2. Pressure Balancing: Dynamically controls pump speed, stabilizing pipe network pressure at 0.3-0.4 MPa and reducing leakage by 10 percentage points;

3. Backwash Optimization: Automatically initiates backwash based on filter tank pressure differential, saving 30% water.

3. Data and Compliance Management

1. Data Traceability: Water quality/equipment/energy consumption data is backed up locally and in the cloud, with a retention period of ≥5 years, in compliance with the "Standards for Drinking Water Hygiene";

2. Intelligent Reporting: Automatically generates daily/monthly water quality testing and energy consumption statistics, with one-click integration into the environmental protection monitoring platform;

3. Permission Hierarchy: Administrator/Operation and Maintenance personnel have separate operational permissions, ensuring traceability of key operations. Zero compliance risk, 90% increase in report preparation efficiency.

3. Power and Operations Management

1. Power Monitoring: Real-time monitoring of voltage fluctuations and current overloads to prevent equipment outages.

2. Maintenance Reminders: Automatically generates plans for pump lubrication and instrument calibration based on operating hours, reducing equipment failure rates by 35%.

Equipment lifespan extended by 2-3 years, reducing operations and maintenance costs by 25%.

II. Core Advantages

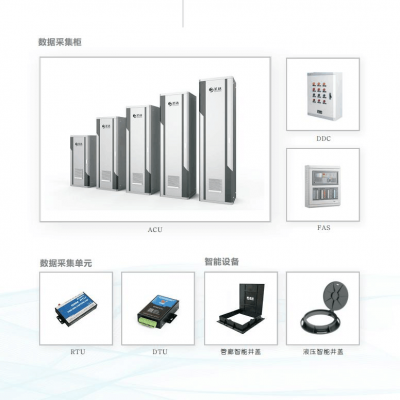

1. Strong Compatibility: Supports integration with sensors and PLCs from major brands such as Hach and Siemens, eliminating the need to replace existing equipment and reducing retrofit costs by 40%.

2. High Stability: Industrial-grade hardware architecture enables 24/7 continuous operation, with a system failure rate of less than 0.3% and data collection accuracy ≥99.8%.

3. Significant Energy Savings: After implementation at a prefecture-level water plant, leakage rates have been reduced from 15% to 5%, saving over 2 million tons of water annually.

4. Easy-to-Use and Adaptability: The flow-chart-based user interface allows operations and maintenance personnel to get started in under an hour, supporting integrated management and control of multiple water supply scenarios.

III.. Service Guarantee

1. Rapid Deployment: We provide a full-process service from "on-site investigation - solution design - commissioning and launch," enabling implementation within 30 days for small and medium-sized water plants.

2. Operations and Maintenance Support: 24/7 technical hotline, remote troubleshooting response time ≤ 2 hours, and on-site resolution of major issues within 48 hours.

3. Free Training: We offer a comprehensive "practical training + video manual" program covering all positions, including administrators, operators, and laboratory technicians.

Previous:Nothing

Associated product

Intelligent SCADA System for Waterworks

Intelligent SCADA System for Wastewater Treatment Plants

Cubic garage control system

Chiller group control system

Intelligent SCADA System for WaterworksNo information